Cabinet Dyeing Machine

Being a client-centric organization, we are engaged in offering a wide array of Cabinet Dyeing Machine & Bleaching machine. Our skilled professionals manufacture these machines, from high quality raw material, using the latest technology. In ahead of their final dispatch, our offered machines are thoroughly checked by our quality inspectors against varied quality parameters. Available with us, in a number of specifications, these machines are highly demanded in the market. we can supply from 20kg to 200kg or more capacity models with carrier arrangemant and temp controling etc.

Textile Processing Plants

Textile Processing Plants Thread Processing Machine

Thread Processing Machine Silk Processing Machine

Silk Processing Machine Wool Processing Plant Machine

Wool Processing Plant Machine Textile Processing Plant Machine

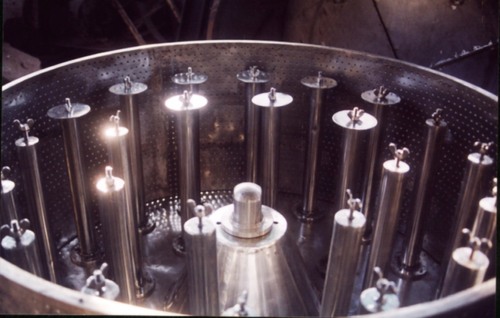

Textile Processing Plant Machine Mechanical Seal

Mechanical Seal Surgical Cotton Processing Machine

Surgical Cotton Processing Machine

.jpg)