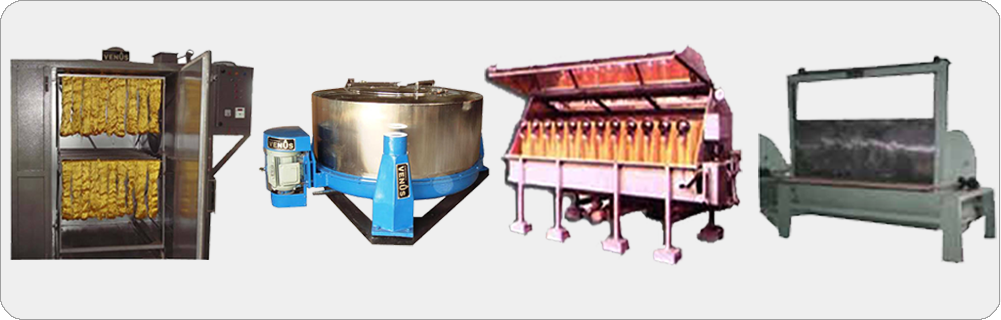

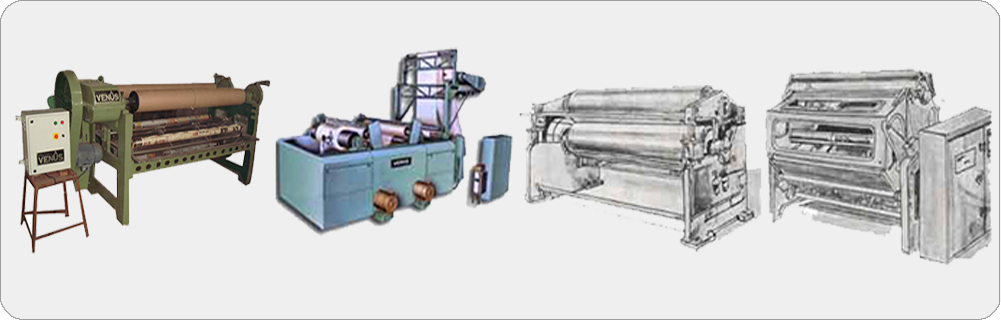

Continuous Carpet Cum Hark Dryer

Product Details:

- The Continuous Carpet Cum Hark Dryer is designed in a most compact way taking care of power & stream consumption as well as Next To Nil Future Maintenance by providing split fan shafts & Elliptical tube finned type heaters for efficient heating at lower steam consumption

- Each compartment is having enough Airo-dynamic air jets at the top & bottom with individual dual suction fan giving more volume of hot air with less H.P. gives maximumheating and save power

- The Complete chain is manufactured out of specialized steel duly heat treated to avoid elongation of chain and also the roller bush type design gives friction free movement on the chain race and long Life

- The Dryer is completely insulated by sandwiched glass wool panels from all sides to avoid Air leakage in the department & also save and preserve heat energy inside for better efficiency during process

- Effective exhaust system with timer will be provided to balance moisture according to the operational requirement

- A centralize Streamline control panel with neon light Digital temp indicator with individual push button will be provided

Textile Processing Plants

Textile Processing Plants Thread Processing Machine

Thread Processing Machine Silk Processing Machine

Silk Processing Machine Wool Processing Plant Machine

Wool Processing Plant Machine Textile Processing Plant Machine

Textile Processing Plant Machine Mechanical Seal

Mechanical Seal Surgical Cotton Processing Machine

Surgical Cotton Processing Machine