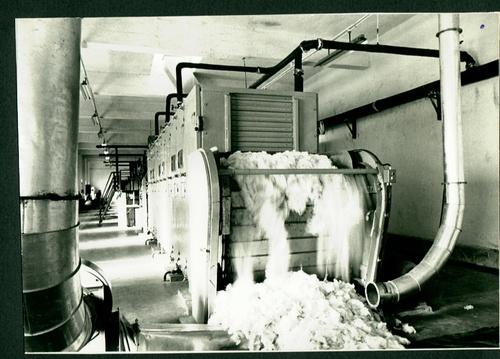

Wet Cotton Opener

The Wet Cotton Opener is most versatile machine can be used for opening Wet Cotton Fiber and Surgical Cotton Plant in Ahmedabad other siminilar fibers in surgical cotton plant and other allied fiber producing mills. The machine is equipped with anticorrosive endless lattice to feed the fiber to the high speed running spiked drum to for opening of the fiber and can be delivered at the other end of machine.

Features:

- Sturdy structure is provided for vibration free movement.

- Drive is equipped with reduction gearbox and gear wheels

- Easy cleaning and maintenance can be provided due to flexible covering guards

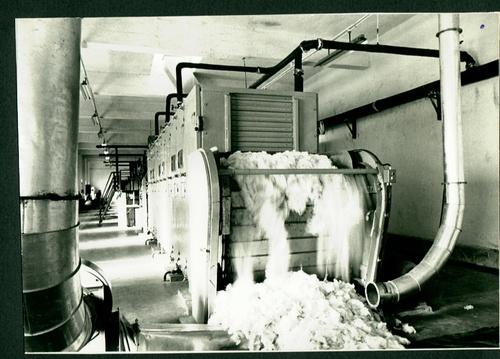

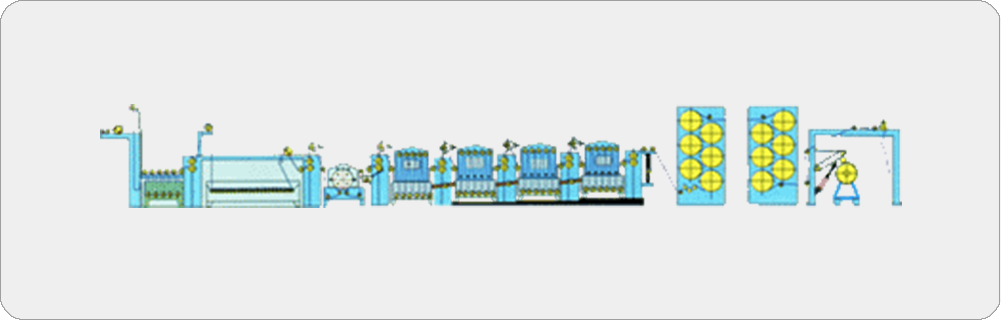

Continuous Conveyor Dryer

The High Lighted Points of “Venus” Conveyor Type Continuous Fiber Dryer.

- The complete dryer is insulated from all the sides by insulating panels in all six sides.

- Each Chamber is having bottom and top Fin type heaters with filters to evenly heat the hot air and evenly dry the material, which is moving on the Conveyor. Filters are preventing choking of fins of the heaters.

- The material on the conveyor is moving in an opposite direction then the serpentine Airflow which dries the material on the Conveyor from Top and Bottom evenly. In other dryer, Air is blown only either from the top or from the bottom whereas here from both the sides.

- Each Chamber is having separate big Blower running in Ball bearing house in separate housing for continuous powerful airflow with V-belt drive by individual motor. The driving Motors are outside and away from heating zone for a longer life.

- There is an overhead duct from 1st Chamber to the last Chamber with dumper arrangement to re-circulate the hot air or to blow out if saturated with manual dumper setting as per the process requirement. This saves energy due to re-circulation.

- The conveyor & inner Portion is painted with rust proof Aluminium paint and Surgical Cotton Plant in Ahmedabad to complete machine is painted from inside also with Silver Aluminium paint.

- The Chains are manufactured out of heat-treated EN-8 material with all the rollers and pin grounded on center less grinder for additional life and next to nil wear and tare The Chain is guaranteed for 5 years, two shift working in normal conditions. It is moving on an additional guide hence the structure is not damaged.

- A complete conveyor can be equipped with either a step pulley variable drive with A.C. Inverter or DC variable speed drive for setting different type of stay time according to the material to be dried as per client’s choice at an extra cost.

- All Chambers are in assembled condition and provision is kept to add more chambers if required in future.

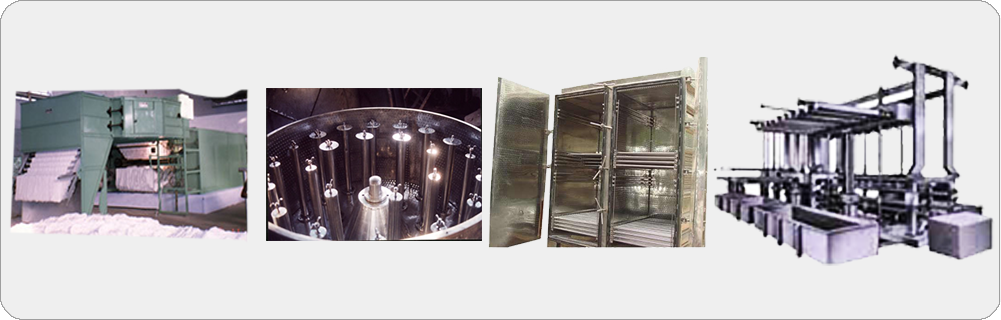

Cake Type Hydro Extractor

HIGH-LIGHTED POINTS OF HYDRO EXTRACTOR WITH INVERTRE DRIVE WITH

FULLY AUTO CONTROL PANEL.

- The outer Body and Inner basket are fabricated out of Stainless Steel Material for avoids corrosion and frequent painting of the machine.

- The basket is dynamically balanced on balancing machine to avoid wear & tear on bearing due to continuous high speed rotation.

- A convenient single point greasing system on bearings is provided to lubricate the bearings of basket provide long life and avoid periodical maintenance.

- An Imported variable speed Inverter Drive with Auto panel is provided which is saving 40% power as well as avoids mechanical Brake & Clutch system which prevents frequent stoppage for maintenance.

- Two Safety Limit switches are provided, one at the lid and other at the leg of the machine to stop the motion if door is opened or the machine is loaded with imbalance load in the basket to avoid accident & damage to the machine & men during operation.

- Heavy-duty ball bearing and thrust bearings are provided for easy rotation of basket.

- CI sturdy Legs mounted robust based with spring type pendulumalatic suspension is provided for smooth, vibration free rotation long life of machine.

- A Centralized Control Panel for Inverter with timer is provided with machine. Total Auto programming can be done on panels which increase the production & utilization of equipment.

- Pneumatic door opening system with its Control is provided to open & close the lid at an extra cost for bigger diameter basket if required. In which case you have to provides pressurized dry air through moisture separator by your centralize airline to the pneumatic control panel of the machine.

- Basket Capacity of various model, varies with count of Fiber or Fabric or density of the materials hydro extorted.

- We can supply from minimum 6000mm dia. Basket to maximum 1950mm dia. Basket with fully automatic A.C. variable Inverter drive with Auto Panel.

Textile Processing Plants

Textile Processing Plants Thread Processing Machine

Thread Processing Machine Silk Processing Machine

Silk Processing Machine Wool Processing Plant Machine

Wool Processing Plant Machine Textile Processing Plant Machine

Textile Processing Plant Machine Mechanical Seal

Mechanical Seal Surgical Cotton Plant in Ahmedabad

Surgical Cotton Plant in Ahmedabad