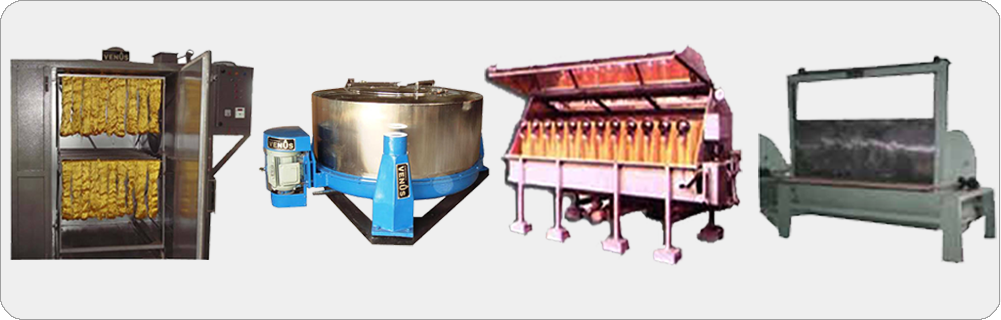

Hydro Extractor with Inverter Drive

HIGH-LIGHTED POINTS OF HYDRO EXTRACTOR WITH INVERTRE DRIVE WITH

FULLY AUTO CONTROL PANEL.

- The outer Body and Inner basket are fabricated out of Stainless Steel Material for avoids corrosion and frequent painting of the machine.

- The basket is dynamically balanced on balancing machine to avoid wear & tear on bearing due to continuous high speed rotation.

- A convenient single point greasing system on bearings is provided to lubricate the bearings of basket provide long life and avoid periodical maintenance.

- An Imported variable speed Inverter Drive with Auto panel is provided which is saving 40% power as well as avoids mechanical Brake & Clutch system which prevents frequent stoppage for maintenance.

- Two Safety Limit switches are provided, one at the lid and other at the leg of the machine to stop the motion if door is opened or the machine is loaded with imbalance load in the basket to avoid accident & damage to the machine & men during operation.

- Heavy-duty ball bearing and thrust bearings are provided for easy rotation of basket.

- CI sturdy Legs mounted robust based with spring type pendulumalatic suspension is provided for smooth, vibration free rotation long life of machine.

- A Centralized Control Panel for Inverter with timer is provided with machine. Total Auto programming can be done on panels which increase the production & utilization of equipment.

- Pneumatic door opening system with its Control is provided to open & close the lid at an extra cost for bigger diameter basket if required. In which case you have to provides pressurized dry air through moisture separator by your centralize airline to the pneumatic control panel of the machine.

- Basket Capacity of various model, varies with count of Fiber or Fabric or density of the materials hydro extorted.

We can supply from minimum 600mm dia. Basket to maximum 1950mm dia. Basket with fully automatic A.C. variable Inverter drive with Auto Panel.

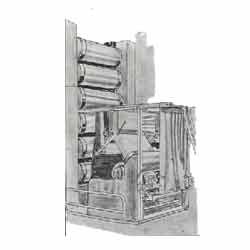

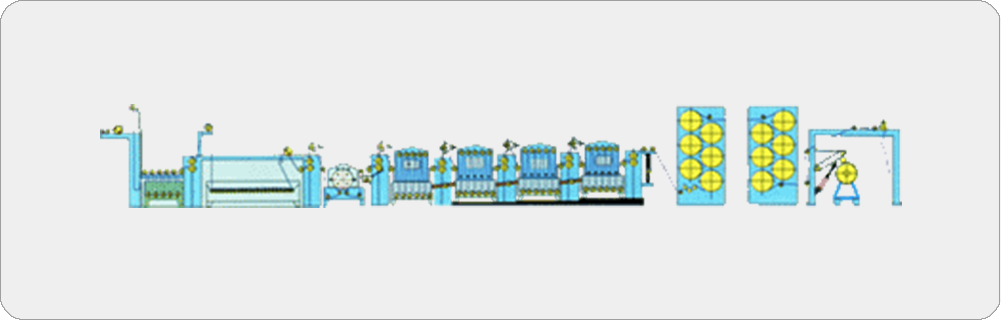

Continuous Beaching Range with Combi Steamer

Continuous Bleaching Plant with Combi Steamer

Steam Ranges for continuous preparation; bleaching and dyeing were developed after years of prctical experience in continous wet processing. The C.S. 200 Roller Bed preparation steamer, is a simple machine with increased speed capacity and is adaptable to new or existing plant.Its process affords sillicate-free peroxide bleaching and more even pre-treatment then discontinupus techniques.The D.S. 40 Roller to Roller Dye Steamer also incorporates all up-tp-date advances in enginering design and process technology.

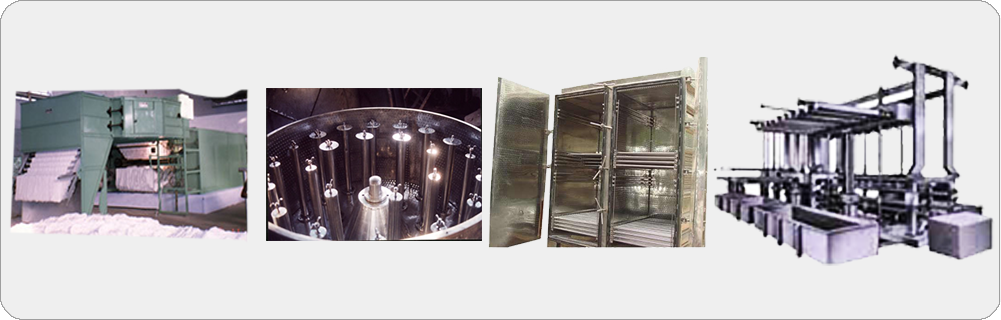

Semi Auto Jigger Machine with Hood & Open Type.

This is a most versatile Dying Jigger equipped with tention less Inverter drive which facilate the machine to the dye finner silk fabric to courser fabric of any type. The machine is equipped with control pannel with digital temprator indicator & controler on request . A wider width machine is also equiped with S.S. Circulating pmping ystem. Close type machine as well as open type machines ase also available.All rollers & tank are stainless steel with heavy duty break drums & gearbox is supplied.

Features:

- Rugged design

- Precisely engineered

- Corrosion resistance

- Steam Line Electric Control Panel

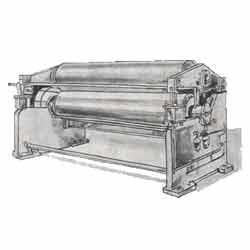

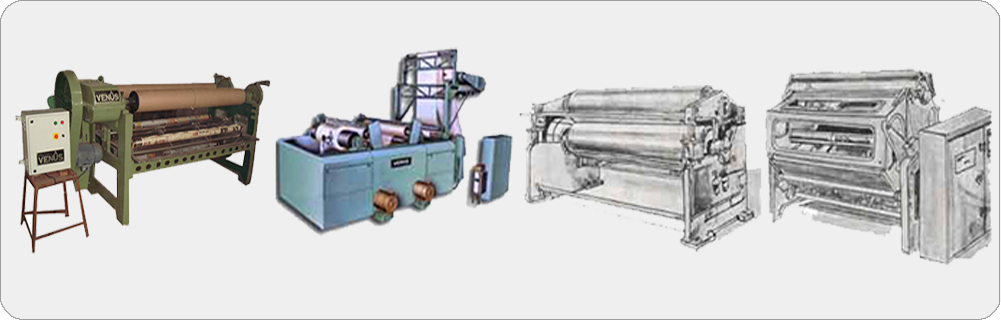

Padding Mangal

Mangles are designed for a variety of purposes with loading upto 12 Tons and bowl width as required. Bowl combinations include soft rubber to soft rubber; soft rubber to hard rubber; rubber to stainless steel ; high expressioon to hard rubber or stainless steel. Many dyejigs have been supplied in india and abroad and have proved thier reliability over many years. They are easily operated and maintenance costs are low. Easily coupled; they are economically priced and are continually being up dated. The current range includes a Sieve Drum Dyejig specially designed for pile type fabrics.

High Speed Drying Range with Mangal

Drying Ranges Can be built to user's specification and designed to work in conjuction with any continuous machinery requiring adrying or Semi Drying Process. The dryers are Sturdily built to simple trouble-free designs, using first class materials throughout. The Cylinder are fabricated out of stainless Steel matarial from small to wider with dual side steam supply. Teflon coated cylinder can be also in corporated as per the client requirment. All cylinders are mounted on study steal running in heavy duty ball bearings for trouble free working. Necessary inlet-outlet steam line with routry joints are provided. an invertor drive with Control panel is provided for independant or synchronize working of the machine.

Textile Processing Plants

Textile Processing Plants Thread Processing Machine

Thread Processing Machine Silk Processing Machine

Silk Processing Machine Wool Processing Plant Machine

Wool Processing Plant Machine Textile Processing Plant Machine

Textile Processing Plant Machine Mechanical Seal

Mechanical Seal Surgical Cotton Processing Machine

Surgical Cotton Processing Machine