Textile Processing Plants

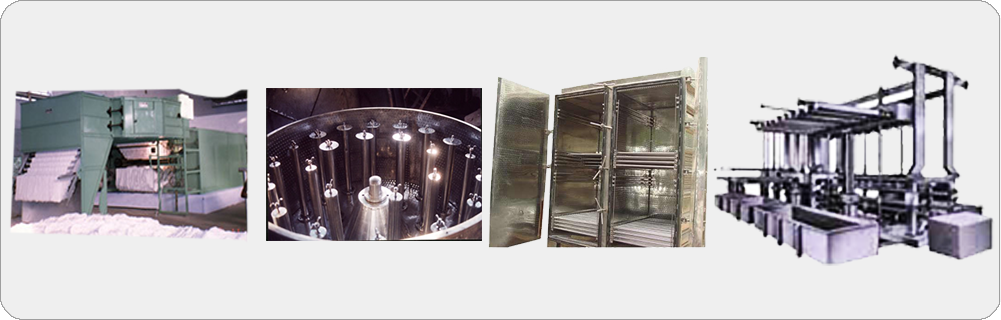

Textile Processing Plants Thread Processing Machine

Thread Processing Machine Silk Processing Machine

Silk Processing Machine Wool Processing Plant Machine

Wool Processing Plant Machine Textile Processing Plant Machine

Textile Processing Plant Machine Mechanical Seal

Mechanical Seal Surgical Cotton Processing Machine

Surgical Cotton Processing Machine

venuseng@dataone.in | rajivthakore@gmail.com

Client Satisfaction

We are a client centric organization and effort hard to offer our clients optimum satisfaction. Assisted by a team of experienced professionals, we ensure that our products are manufactured in...

Quality Standards

Being a quality oriented firm, we make certain to provide high quality and defect free products to our valuable clients. Our professionals are dedicated to offer our clients supreme quality...

Our Infrastructure

We are supported with a highly advanced infrastructure that enables us to carry out our business operations in an organized manner. Spread across a wide area, this facility is segregated into different...

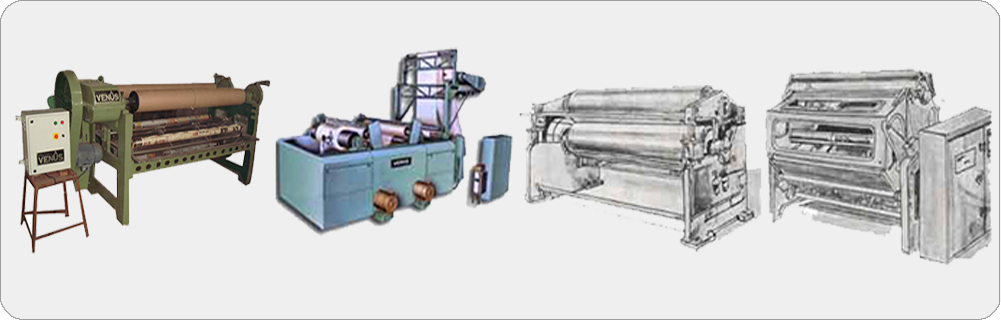

About to The Venus Engineering Co

Incepted in the year 1941, at Ahmadabad (Gujarat, India), we “The Venus Engineering Co.,” are a well-renowned manufacturer,Hydro Extractor Machine in Ahmedabad, exporter and supplier of a comprehensive range of Continuous Carpet Cum Hark Dryer, Mechanical Seal, Thread Processing Machine, Silk Processing Machine, Wool Processing Plant Machine, Textile Processing Plant Machine and Surgical Cotton Processing Machine. These are designed and manufactured using the finest quality components and sophisticated technology. These machines are designed with high level of precision in order to meet the international quality standards. The offered machines are highly appreciated by our clients for their features like excellent performance, easy maintenance, robust construction, energy efficiency, easy installation, rugged design and longer service life. Available in various technical specifications, these machines can also be customized as per the requirements of the clients. Owing to our excellent quality, we have been to cover all sectors of Textile by supplying machinery for Fabric, Fiber & Yarn for Cotton, Woolen, Blended, Silk & Woven.

We are backed by an ultra-modern infrastructural facility that is spread across a broad area. Our infrastructure is segregated into various functional units like manufacturing, quality testing, research & development, warehousing & packaging, etc. Further, our high-tech manufacturing unit makes us able to manufacture these machines in timely manner. We carry out variety of quality processes throughout manufacturing process that make certain only high quality machine are delivered to the clients. The raw material that we use in the production process is procured from reliable vendors. Also, the raw material is precisely checked by our quality controllers on various parameters. Further, our whole business procedures are handled by team of accomplished professionals, who work in close co-ordination with clients in order to fulfill their wide demands in a timely manner. We have divided our team into various sections like quality controllers, research associates, management personnel and sales & marketing executives. These professionals work round the clock to cater to the wide needs of the clients in an effective manner

Being a client-centric organization, we left no stone unturned when it comes to client satisfaction. Our industry experts ensure that offered products are fabricated in tandem with the specifications laid down by the clients with the utmost quality. These products are quality tested on various parameters to make fit on customer's expectations. We have webbed wide distribution network that help us in supplying these products in timely manner. We maintain a level of transparency in all our dealings, which help us attain maximum level of client contentment. Due to our ethical business policies, prompt delivery, competitive prices and client-centric approach, we are constantly establishing a long list of satisfied clients across the market.

Under the proficient guidance of our mentor, “Mr. Rajiv Thakore (Director),” we are able to maintain the prominent position in the domain amid in this cut-throat market competition.

The Venus Engineering Co. has been manufacturing a wide range of Continuous Processing Plants for Scouring, Carbonizing, Bleaching, Dyeing & Print Washing for Cotton synthetic, Blended, Woollen and Delicate Silk Yarn, Fabric & Fiber. It has in a way revolutionized the Textile Wet Processing Industry in India & abroad.

"Venus" Print Washers and open width continues Bleaching Range with Combi Steamer incorporated with Jet Drum Washers, have proved their performance as Super Beaching Range and Super Washer for reactive Print Washing, which helps increase the washing efficiency and finish of fabrics to a greater extent. Those offers the latest technology for efficient washing of reactive prints and fine fabrics, keeping in tune with the rapidly changing fashion trade, always volatile by constantly updating their designs based on market feedback. The company designs and manufactures machinery to give most economic use of Water, Power & Steam energy.

"Venus" known for their "Quality, Reliability, Rigidity and Simplicity." It is the first in the country to design and manufacture a modern Continuous Loose Wool Scouring Plant with Conveyor Dryer, besides supplied such units to leading woollen Mills in India like Raymonds Ltd. and Digjam VXL Ltd. as well as many other leading scouring & wool processing units in Amritsar & Bhadohi like Ms Obbttee ltd., Eastern Exports, ABC Exports etc. Carpet Manufacturers and the same was also exported to the developing Countries.

According to Director, Mr. Rajiv Thakore, the company possesses a comparable technical knowhow for textile processing machine building from the reputed textile engineering industries of the world. In recognition of its performance in saving substantial foreign exchange, Venus had received "Import Substitution" award from the Gujarat Chembers of Commerce and Industry for developing "Wool Scouring Plant" indigenously & exporting the same also.

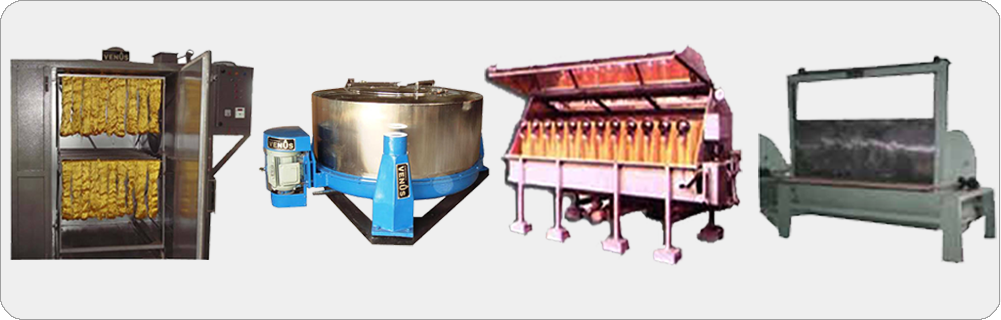

Most of the leading Sewing Threads manufacturing units in the country, including Madura Coats and Vardhman Group, are using the Venus Range of Machines for the last several years for Cotton Dyeing and also using conveyor type, Hydro extracting & Continuous Hank Pole Dryer Machine as well as fiber dryers.

Most of all leading Yarn Mills in India and small yarn dye house in South, Karur, Erode & Salem area are equipped with "Venus" Continuous Hank Dryer, because of its low Steam & Power Consumption and high out put compared to other machines available in the market.

Besides specializing in designing and manufacturing of machinery for different varieties of textile fabric, the company is successfully serving to the complete Handloom and Silk sector by supplying Auto Spray dyeing plants and continuous type Hank Dryer as well as Hydro-extractor, Rinsing & We are also supplying equipments for De-gumming equipments for Silk,Yarn and Fiber. Our Silk Processing Plants are supply to all leading export oriented units of India.

Most of all small & big dye houses of Wool and Carpet manufacturers of North India are using "Venus" Yarn Scouring and Loose Wool Scouring Machine, Conveyor type Continuous Silk Hank & Fiber Dryer, continues 4 meter wide carpet dryer & lataxing machine, S.S Hydro-extractor with inverter drive, Cabinet & Carrier dyeing Machines.

In nutshell "Venus" is covering all sectors of Textile by supplying machinery for Fabric,Hydro Extractor Machine in Ahmedabad, Fiber & Yarn for Cotton, Woollen, Blended, Silk & Woven.

The "Venus" range of processing plants can be broadly classified in five major products categories as under:

- Textile Processing

- Silk Processing

- Woollen Processing

- Thread Processing

- Carpet & Lataxing Dryer

- Surgical cotton processing

Client Satisfaction

We are a client centric organization and effort hard to offer our clients optimum satisfaction. Assisted by a team of experienced professionals, we ensure that our products are manufactured in compliance with the international quality standards using optimum grade raw material and advanced technology. Our professionals work in close co-ordination with the clients to identify their specific requirements. Owing to our ethical business policies, transparent dealings, client centric policies and timely delivery approach, we have been able to attain optimum satisfaction of our clients.

Our Infrastructure

We are supported with a highly advanced infrastructure that enables us to carry out our business operations in an organized manner. Spread across a wide area, this facility is segregated into different units like production, quality control, R&D, warehousing & packaging, etc. Work in a streamlined manner to ensure trouble free the production process, this facility is well-equipped with high-tech machines and advanced technologies. The installed machines and technology are operated by our experienced technicians.

Quality Standards

Being a quality oriented firm, we make certain to provide high quality and defect free products to our valuable clients. Our professionals are dedicated to offer our clients supreme quality products as per their specific needs. Also, we have devised strict quality management policies that are strictly followed throughout business process. In order to achieve high quality standards in our products, our quality experts vigorously check entire manufacturing process, right from procurement of raw material till delivery at clients’ end.